A newly reported Sulfur-Based Battery design could significantly increase how quickly stored energy is delivered, according to laboratory research discussed by scientists and engineers in early 2026. The work proposes a different electrochemical reaction pathway that may overcome long-standing performance limits affecting electric vehicles, consumer electronics, and renewable-energy storage.

Table of Contents

New Sulfur-Based Battery Concept

| Key Fact | Detail |

|---|---|

| Core discovery | New electrochemical reaction involving sulfur improves power delivery |

| Why it matters | Could enable faster EV acceleration and rapid charging |

| Current stage | Laboratory prototype, not yet commercial |

What the Sulfur-Based Battery Research Shows

A shift in how energy moves inside batteries

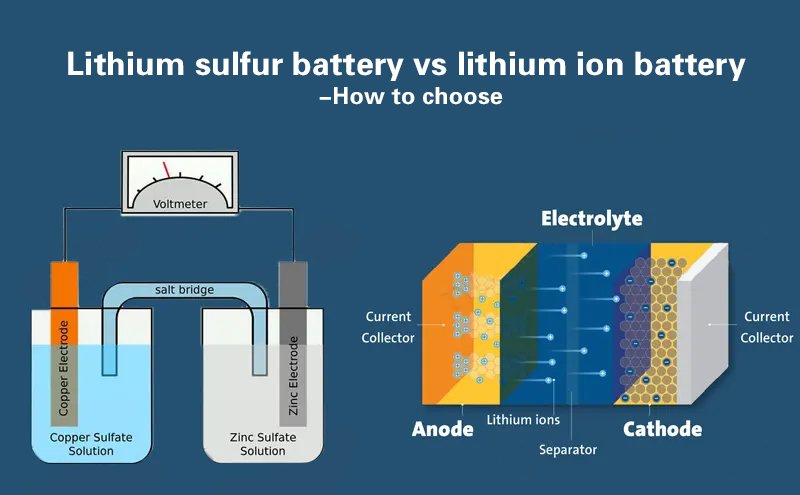

Traditional lithium-ion batteries store energy by moving lithium ions between two electrodes. Their performance depends largely on how quickly chemical reactions occur within the cathode material.

In the new Sulfur-Based Battery concept, researchers redesigned the reaction so sulfur participates more directly in the exchange of electrons. Scientists say this alters the reaction kinetics — the speed of electrochemical processes — allowing higher power output.

“Power density depends on reaction speed,” materials researchers explained in technical analysis of the findings. Faster reactions allow a battery to release large amounts of energy quickly, which is critical for electric-vehicle acceleration and grid-level power stabilization.

Why Power Density Matters More Than Many Realize

Energy density measures how long a battery lasts. Power density measures how fast electricity can be delivered.

Electric vehicles require both. A vehicle merging onto a highway demands an immediate burst of electricity, not just long driving range.

Current lithium-ion batteries sometimes struggle with sustained high loads and heat buildup. High current flow accelerates degradation and increases cooling requirements.

Researchers say the Sulfur-Based Battery reaction pathway could address this constraint by enabling faster electron transfer inside the cell.

Sulfur has another advantage: availability. It is produced globally in large quantities as an industrial by-product of oil refining and natural gas processing. Because it is abundant, the material cost could be dramatically lower than nickel-rich lithium-ion cathodes.

Long-Standing Challenges With Lithium-Sulfur Technology

The “shuttle effect” problem

Scientists have explored sulfur batteries since the 1960s. Despite strong theoretical performance, practical applications remained limited.

The largest obstacle has been the “polysulfide shuttle effect.” During charging and discharging, intermediate sulfur compounds dissolve and migrate within the battery. This gradually drains capacity and shortens battery life.

Sulfur is also electrically insulating. Slow electron flow limits performance.

The new design attempts to bypass these weaknesses by modifying the reaction chemistry itself rather than only engineering protective coatings or separators.

Battery researchers say altering the electrochemistry could reduce formation of harmful intermediate compounds, potentially improving stability.

Historical Background: Why Scientists Never Stopped Studying Sulfur

Lithium-ion batteries, commercialized in the early 1990s, became dominant because they balanced reliability, cost, and performance. However, their energy density is approaching practical limits.

For decades, scientists searched for a successor. Lithium-sulfur systems remained attractive because, in theory, they can store roughly two to three times more energy per kilogram than typical lithium-ion batteries.

The challenge has always been durability. Many experimental cells worked well initially but degraded after tens of cycles.

The new Sulfur-Based Battery concept is significant because it targets the fundamental chemistry — not just the engineering — of the battery reaction.

Implications for Electric Vehicles and Renewable Energy

EV performance and charging

Automakers increasingly need batteries capable of rapid charging without overheating. Fast charging requires materials that tolerate high electrical currents.

A high-power Sulfur-Based Battery could potentially:

- reduce charging time

- reduce cooling system weight

- lower reliance on critical metals

Battery cost remains one of the largest contributors to electric-vehicle pricing. Reducing cobalt and nickel usage could lower manufacturing expenses and improve supply security.

Renewable energy storage

Solar panels and wind turbines produce variable electricity depending on weather. Grid operators therefore need storage systems capable of delivering rapid bursts of energy to stabilize voltage and frequency.

Engineers say the Sulfur-Based Battery could complement long-duration storage by providing rapid power delivery — similar to how capacitors assist electronics.

Environmental and Supply Chain Effects

Battery supply chains depend heavily on mining. Lithium-ion batteries require nickel, cobalt, and manganese, often sourced from a small number of countries.

Cobalt mining, particularly in the Democratic Republic of Congo, has raised concerns over labor practices and environmental impact.

Sulfur, by contrast, is already produced in large volumes as an industrial waste recovery material. Using it in batteries could reduce mining demand rather than increase it.

Environmental analysts note this could lower the ecological footprint of battery production and reduce geopolitical supply risks.

Safety Considerations

Battery safety is a critical concern following several high-profile lithium-ion fire incidents in consumer electronics and electric vehicles. Most fires result from thermal runaway — a chain reaction caused by overheating.

Researchers say sulfur chemistry may reduce some risks because the cathode does not rely on oxygen-releasing metal oxides found in certain lithium-ion batteries.

However, experts caution that any new battery chemistry must undergo years of testing under extreme temperatures, impact conditions, and charging misuse scenarios.

Manufacturing Challenges

Scaling laboratory discoveries into commercial batteries is often the most difficult step.

Manufacturers must solve:

- consistent electrode coating

- electrolyte compatibility

- industrial production speed

- long-term reliability

Battery factories require billions of dollars in investment. A new chemistry must integrate into existing manufacturing lines or justify entirely new ones.

Engineers note that even successful laboratory results typically require five to ten years before mass adoption.

Expert Perspective and Caution

Battery specialists emphasize the research remains early-stage.

Laboratory cells differ greatly from large battery packs used in vehicles. Scaling production requires solving durability and quality-control challenges.

“Many promising chemistries perform well in small prototypes but encounter issues in large-format cells,” energy storage analysts have noted in industry studies.

Key unanswered questions include:

- charge cycle lifespan

- temperature tolerance

- mechanical stability

Automakers typically require batteries to survive more than 1,000 full charge cycles while maintaining capacity.

Broader Context: Competition With Other Battery Technologies

The Sulfur-Based Battery enters a competitive landscape that includes:

Solid-state batteries – Focus on safety and energy density

Sodium-ion batteries – Focus on low cost and material availability

Advanced lithium-ion chemistries – Focus on incremental improvement

Each addresses a different weakness of current batteries.

Rather than replacing lithium-ion entirely, analysts say future energy systems may use multiple battery types optimized for specific purposes.

Economic Impact

If successful, the Sulfur-Based Battery could affect several industries:

- automotive manufacturing

- renewable energy infrastructure

- consumer electronics

- aviation and drones

Lightweight, high-power batteries are especially valuable in aircraft and robotics, where weight directly determines performance.

Lower battery cost could accelerate electric vehicle adoption, which economists say is strongly linked to purchase price parity with gasoline vehicles.

Outlook

Researchers will next conduct longer durability testing and scale prototypes into larger cells. Partnerships with manufacturers may follow if performance remains consistent.

For now, the development represents a scientific milestone rather than an immediate commercial product.

One battery engineer summarized the situation cautiously: the chemistry shows “a realistic pathway forward,” but commercial deployment depends on whether laboratory performance can be reproduced in real-world conditions.

FAQs About New Sulfur-Based Battery Concept

What makes a Sulfur-Based Battery different from lithium-ion?

It uses sulfur as the active cathode material and a different electrochemical reaction pathway that may release energy faster.

Will it replace current batteries soon?

No. The technology remains in the research stage and could take several years to commercialize.

Why is sulfur important?

Sulfur is abundant, inexpensive, and lightweight, making it attractive for scalable energy storage.

Is it safer?

Potentially, but safety testing must be completed before any commercial use.