SpaceX’s Next-Gen Super Heavy Booster has completed four days of extreme cryogenic testing at the company’s Starbase facility in South Texas, marking a significant engineering milestone for the broader Starship program. The multi-day test campaign validated structural upgrades to the first-stage booster, a critical component in SpaceX’s effort to develop a fully reusable heavy-lift rocket system capable of future orbital launch missions.

The booster endured repeated cycles of super-cooled liquid nitrogen loading and high-pressure stress tests without structural failure, a key benchmark before engine installation and static fire testing.

Table of Contents

SpaceX’s Next-Gen Super Heavy Booster

| Key Fact | Detail |

|---|---|

| Test Duration | Four days of cryogenic pressurization cycles |

| Location | Starbase (Massey’s Test Site), Boca Chica, Texas |

| Engine Configuration | 33 methane-fueled Raptor engines |

| Regulatory Oversight | Federal Aviation Administration required for launch |

SpaceX’s Next-Gen Super Heavy Booster Validates Structural Improvements

The successful cryogenic testing campaign simulates the extreme thermal and mechanical stresses the rocket will face during launch. Engineers filled the booster’s tanks with liquid nitrogen, an inert substitute for liquid methane and liquid oxygen.

Cryogenic testing evaluates how metal structures respond to temperatures nearing minus 300 degrees Fahrenheit. At such temperatures, stainless steel contracts significantly. Any structural weakness in weld seams or tank domes can cause rupture under pressure.

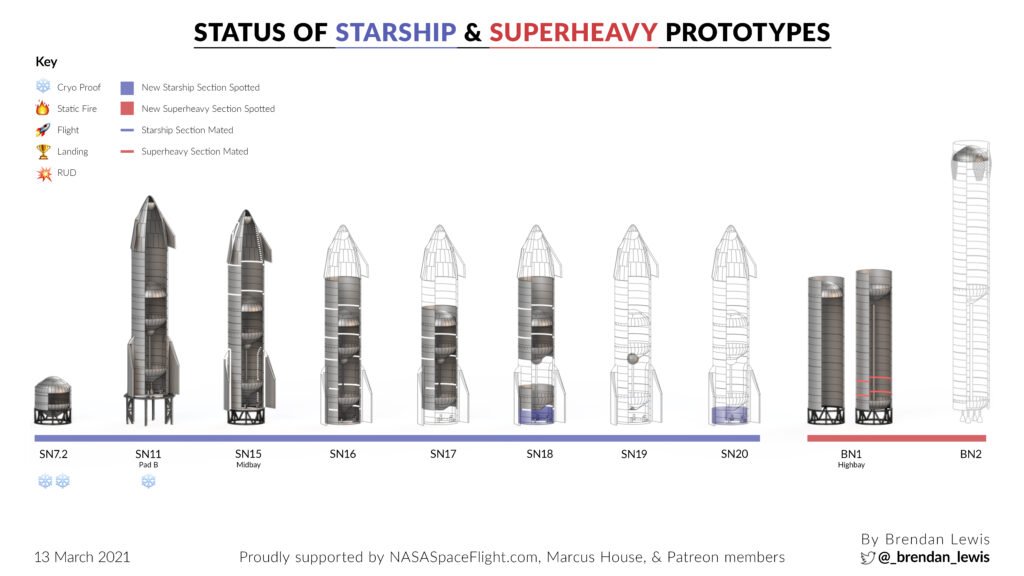

Earlier Super Heavy prototypes experienced failures during similar proof tests in past development phases. According to publicly documented SpaceX updates between 2019 and 2021, several early Starship and booster variants burst during pressurization experiments, prompting design revisions.

Industry analysts say surviving repeated cryogenic cycles suggests measurable manufacturing progress.

“Consistency in weld quality and load distribution is essential for a vehicle this large,” said Dr. Laura Forczyk, an aerospace analyst and founder of Astralytical. “Passing multi-day cryogenic testing does not eliminate all risk, but it significantly improves confidence in structural integrity.”

Engineering Scale: Why This Booster Is Different

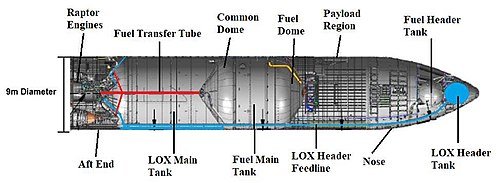

Standing approximately 230 feet tall, SpaceX’s Next-Gen Super Heavy Booster is among the largest and most powerful first-stage rockets ever constructed. Its 33 methane-fueled Raptor engines are designed to generate more than 16 million pounds of thrust at liftoff.

That thrust level exceeds that of NASA’s Saturn V rocket and rivals NASA’s Space Launch System (SLS), according to NASA technical comparisons.

Unlike expendable rockets, Super Heavy is designed for reusability. Following stage separation, the booster is intended to perform a controlled descent and return to the launch site, where it will be caught by mechanical arms attached to the launch tower — a recovery method unique in modern rocketry.

SpaceX has described this approach as central to lowering launch costs and increasing launch cadence within the commercial space industry.

Cryogenic Testing: A Crucial Phase Before Engine Integration

Cryogenic testing focuses on structural resilience, not propulsion performance. By using liquid nitrogen rather than methane and oxygen, engineers can pressurize tanks without combustion risk.

The booster is filled, drained, and repressurized multiple times to simulate launch-day conditions. Sensors monitor tank deformation, stress loads, and weld behavior.

If the booster had failed during this stage, engineers would need to analyze fracture patterns, revise structural reinforcements, and potentially delay upcoming orbital launch attempts.

Instead, the four-day test campaign concluded without visible rupture, according to footage and updates shared by aerospace observers and confirmed by SpaceX activity logs.

The next step will likely involve installation of the full suite of Raptor engines, followed by static fire testing. During a static fire, engines ignite briefly while the booster remains secured to the pad.

Context: The Booster’s Role in the Starship Program

The Super Heavy booster forms the foundation of the Starship launch system. Once separated in flight, the upper-stage spacecraft continues toward orbit.

NASA selected a variant of Starship to serve as the Human Landing System for its Artemis program, which aims to return astronauts to the Moon. NASA officials have repeatedly stated that commercial partner progress remains vital to Artemis timelines.

“Continued testing milestones are critical to ensuring flight readiness,” NASA officials said in previous agency briefings regarding commercial lunar systems.

The success of SpaceX’s Next-Gen Super Heavy Booster therefore carries implications beyond private industry. It affects national space policy, lunar exploration timelines, and international competition in heavy-lift capability.

Regulatory Oversight and FAA Approval

Before any orbital launch attempt, SpaceX must secure FAA approval. The Federal Aviation Administration oversees commercial launch licensing, environmental assessments, and public safety compliance.

Previous Starship launches required environmental mitigation reviews due to debris dispersal and launch pad damage. Following earlier flights, regulators mandated modifications to pad infrastructure and environmental safeguards.

An FAA spokesperson previously stated that license determinations depend on safety reviews and environmental compliance verification.

The agency has not announced a confirmed timeline for the next Starship launch.

Market and Industry Implications

The commercial space industry has grown rapidly over the past decade. SpaceX currently leads global launch frequency through its Falcon 9 program, which achieved record missions last year.

Starship represents the company’s next generation of heavy-lift capability. If operational, it could reduce cost-per-kilogram to orbit and enable large-scale satellite deployments, deep-space missions, and commercial cargo transport.

Todd Harrison, a defense space analyst at the American Enterprise Institute, noted that reliability remains the decisive factor.

“Scale alone does not define success,” Harrison said. “Demonstrated repeatability and safety are what ultimately reshape the market.”

Competitors, including Blue Origin’s New Glenn rocket and United Launch Alliance’s Vulcan rocket, are also pursuing heavy-lift and partially reusable systems.

Technical Challenges Ahead

Although structural cryogenic testing succeeded, several major hurdles remain:

- Full engine integration and ignition reliability

- Booster reentry control and landing precision

- Heat shielding durability

- Regulatory compliance for higher launch cadence

Rocket development historically involves iterative setbacks. SpaceX founder Elon Musk has publicly acknowledged that multiple test flights may fail before reaching routine operations.

The company’s rapid development model emphasizes data collection from real-world testing rather than extended simulation phases.

Environmental and Community Considerations

Launch operations at Starbase have drawn attention from local residents and environmental groups. Concerns have focused on wildlife disruption, coastal habitat protection, and debris from test flights.

Federal environmental assessments required SpaceX to implement mitigation measures before future launches. These include debris containment upgrades and monitoring of nearby wildlife refuges.

SpaceX has stated that it works in coordination with state and federal regulators to comply with environmental standards.

Looking Ahead

The successful cryogenic campaign reduces structural uncertainty in SpaceX’s Next-Gen Super Heavy Booster, but it does not guarantee immediate orbital success.

Engine installation, static fire validation, and FAA approval remain pending steps. Aerospace observers expect additional testing in the coming months.

For now, the milestone signals measurable engineering progress in one of the most ambitious aerospace projects currently underway.

The timing of the next orbital launch will depend on regulatory clearance and successful engine testing, but the structural foundation of the booster appears stronger than in previous iterations.

FAQ

What is SpaceX’s Next-Gen Super Heavy Booster?

It is the first-stage rocket of the Starship system, designed to lift the spacecraft into orbit using 33 methane-fueled Raptor engines.

What is cryogenic testing?

It is a structural stress test using extremely cold liquids to simulate launch conditions and verify tank integrity.

Does this mean Starship will launch soon?

Not necessarily. Engine tests and FAA approval must occur before an orbital attempt.

Why is reusability important?

Reusable boosters can reduce costs and increase launch frequency, potentially reshaping the commercial space industry.